If you possess white gold jewellery, you’re likely familiar with the phrase “Rhodium plating”. Rhodium plating is a specialized process in which a thin layer of rhodium, a rare and precious metal belonging to the platinum group, is applied to the surface of an object, typically jewellery. Have you ever wondered about what actually happens to your piece throughout this intriguing process? In this blog post, we give you an in depth look at the entire process of rhodium plating from start to finish.

Emery

Emery paper, a versatile tool in the world of jewellery care. It offers a gentle yet effective way to restore the luster of your cherished ring. The first Emery paper we use is a courser grit, to remove heavier scratches, reshape dent areas, remove signs of wear and the sharp edges created from wearing rings together. This is done on the outside of the band using a custom made file like tool, and the inside of the band using a rotary tool.

Repair imperfections

Once the ring has had a course emery, this can reveal some underlying issues. To ensure a perfect finish, the jeweller then goes in and further repairs any imperfections. In this case the jeweller repaired a hole in the band where there was a visible previous sizing join using a laser welder. A laser welder utilizes a focused beam of high-intensity light, which generates an intense heat source, enabling jewellers to perform intricate repairs without the need for traditional soldering techniques.

Burnish & Lighter Emery

The next step is to Burnish the laser repair & then Emery again using a lighter grit. Burnishing gently compresses the raised repaired section further into the piece. As the tool glides over the metal, it smooths out any major scratches, pitting, imperfections, or irregularities, creating a reflective and polished surface. We then use a lighter emery to further smooth the surface ready for pre-polishing.

Stone Tightening

From here we do a thorough check over the rings, to see if they require any stone tightening. With this set, the wedding band required stone tightening. The jeweller used a beading tool to gently push metal back over the stones and reshape the existing claws which had flattened out with general wear. Throughout the process, the jeweller may periodically examine the ring under magnification to verify the claws positioning, and the stones stability. We complete this process under microscope which gives us a close up view 100x higher than general eyesight.

Rubber Wheel & Inside Final Emery

The rubber wheel, often attached to a rotary tool, is another abrasive tool with multiple grit options which are selected based on desired finish and are used to smooth a surface area, and remove signs of wear. For this particular ring, the jeweller used a fine rubber wheel to clean up the bright cut edge on the grain style setting and smooth the surface from wear to avoid removing too much metal. A softer rubber wheel is then used on the setting/claws of the engagement ring to remove heavy scratches.

Pre Polish & Inside Polish

After the ring has had its final emery, it then goes through the first step of polishing. This is done using a goat hair brush and a semi-fine polish compound around stone set areas and inside of the ring. The inside of the ring is then finished with a high shine compound with a fluffy mop style tool which is the final step for the inside of the ring.

Final Polish & Ultra Sonic

The Final polish is done in a 2-step process. The first step is a semi-fine polish compound and a larger goat hair brush setup on a bench grinder, finished with a high-shine polishing compound and a large soft fluffy mop attachment to give the piece a super vibrant shine. From there, it then goes into an ultrasonic. An ultrasonic machine is a device that utilizes ultrasonic waves to clean and remove contaminants from objects. It works by generating high-frequency sound waves which create microscopic bubbles in a liquid cleaning solution. These bubbles implode on the surfaces of the objects being cleaned, creating tiny shock waves that dislodge dirt, grime, and particles.

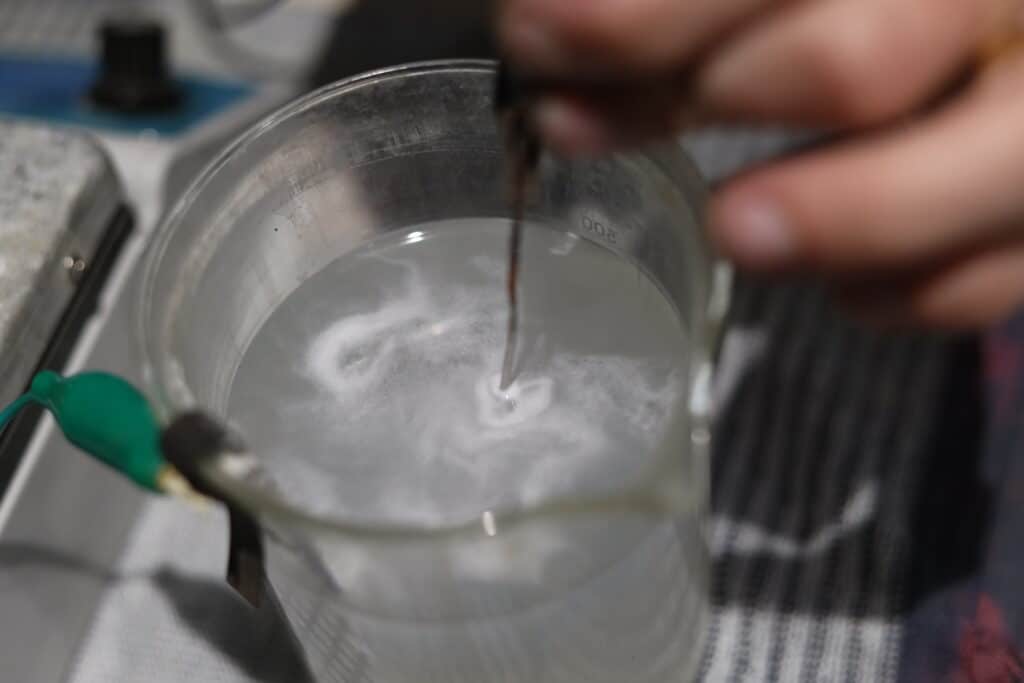

Steam, Rinse, Salt Solution

Once the pieces have come out of the ultrasonic, they then get steamed, rinsed and put in a salt solution. This process involves using an electrolyte solution (usually a mixture of water and a soluble salt) and an electrical current to facilitate a chemical reaction that lifts and dissolves impurities from the jewelry’s surface. This ensures any remaining impurities are removed before rhodium plating.

Rhodium Plating and Quality Control

Once the rings have finished in the salt solution, they are given a good rinse under clean water and are then ready for Rhodium Plating. The Rhodium is an electroplating setup. When the electric current flows through the plating solution, rhodium ions are attracted to the jewellery’s surface. The positively charged rhodium ions are reduced to neutral rhodium atoms, which adhere to the jewellery’s surface. We use a lower voltage and leave the piece in for a longer period of time. This gives the piece the best possible finish and a thicker, longer wearing rhodium plate. Once the ring has finished plating, it is then carefully rinsed and dried, ready for quality control.

Before & After

0488 351 532

1/193-203 South Pine Road, Brendale QLD

Want to book in for a consultation? Contact us today on 0488 351 532 or sales@aurupt.com

[instagram feed=”390″]

© 2024 Aurupt Jewellery

Please provide as much information as you can so we can better assist you with an accurate quote.

Please select a date and time below that would suit and we’ll come back to you with confirmation of your booked in consultation time.